We can now automate almost any repetitive action in manufacturing. But not all automation is created equal – where do you start?

If you’re a manufacturer considering automation, or expanding your existing automation, we probably don’t need to tell you about the benefits of automating some of your production process. We’ve written before about how automation facilitates business continuity, especially in the current pandemic and with European labour laws changing. So how do you go about choosing which equipment you need?

Automation is repetition

In a nutshell, you can probably automate any repetitive function in manufacturing. Tasks like:

- Unloading pallets

- Moving product from A to B

- Cooking

- Dispensing chemicals

- Picking

- Packing products

Where to start with automation

Which step of your process should you tackle first? Consider the sticking points in your process. They’re not always the most labour intensive – there can be hygiene or health and safety considerations that mean it makes more sense to start there.

In food manufacturing, for example, cooking is usually the first step to be automated. It’s sensible – by automating this process, it guarantees an end product that’s not only consistent in quality, but is also hygienic, cooked quickly, efficiently and safely.

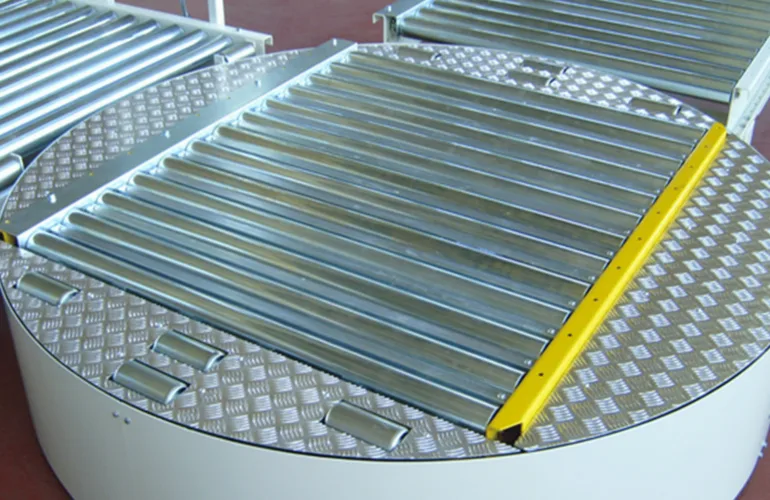

Automatic palletisers often come at the end of the queue, but if you consider the health and safety and production speed implications of human packing and wrapping, it could be a step that will revolutionise your shop floor.

Linking automation

Once you have one area of your automated manufacturing working well, you’ll likely be looking at expanding that to another step. Make sure you think about how these can be linked, whether now or in the future. Consider choosing a compact system at an early stage if you don’t have the floor space to accommodate the robotics for the next step.

Choosing a partner

Choose a supplier that is an expert in automation and engineering project management. Beyond the machine they’re selling, they need to understand your space, scope and the wider implications within your manufacturing environment, and this comes with engineering experience.

PALpack have over 20 years of experience in the field. We will identify and recommend the best possible solution for your automotive palletising needs.