Material handling is an important part of the production process, but it can be a sticking point for some manufacturers. In this blog, we look at how introducing a tray-handling robot into your business could improve your line efficiency and increase throughput.

1. Quicker than manual handling

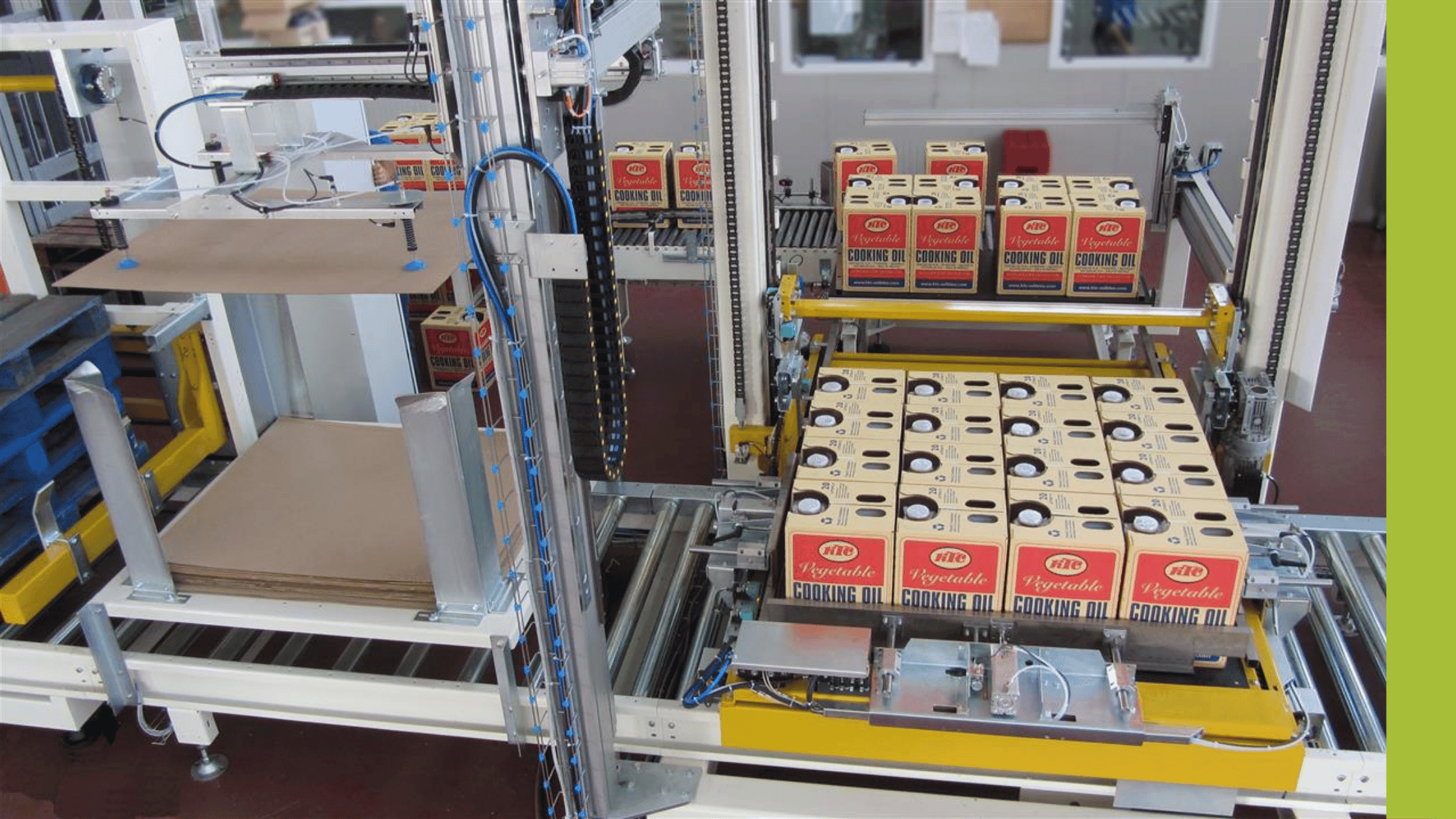

Palletising is one of the last things to be done before a product is shipped or moved into storage. A bottleneck here can have a knock-on effect further up the line, and slow down production.

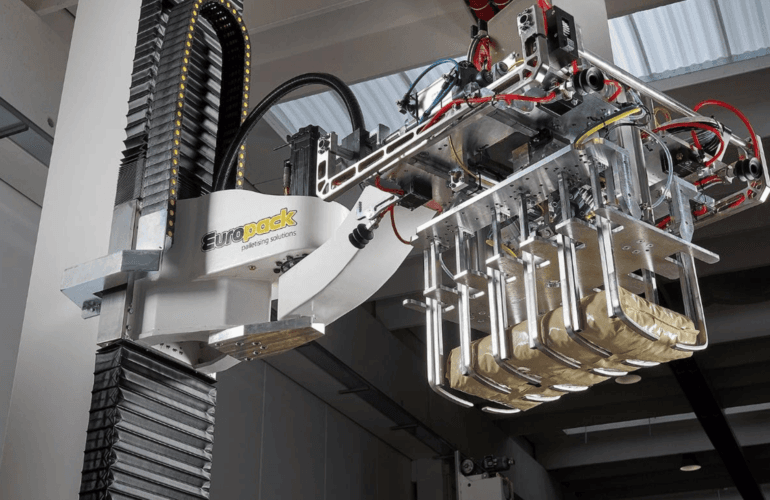

Tray-handling robots are much quicker than people at doing the same job, so they can keep pace with the rest of the production line – even when it’s operating at maximum capacity.

2. Robots are much more reliable

Unlike their human counterparts, robots do not have a lunch break or holidays, and they never phone in sick. You can rely on a robot to do its job without stopping, or slowing down because it’s tired.

What’s more, a robot will consistently take the same amount of time to do a job, and always produce the same results.

3. Increase in productivity and revenue

So robots are quicker than manual handlers, and they have much less downtime. By working more efficiently, tray-handling robots can increase production and revenue. The Lita palletiser, for example, can produce up to 60 packs per minute – a significant increase on the output you might get from two or three people doing the same job manually.

4. Health and safety risks minimised

Material handling often involves a lot of repetition and heavy lifting, which carries a risk of injury. Muscle strain and joint pain are common complaints, and, in some cases, this can lead to repetitive strain injury (RSI).

By using a robot to move pallets and trays instead, you can minimise the risk of injury – and the associated staff absences that cost money in lost production hours.

5. Investing now for long-term profit

A tray-handling robot requires an upfront investment, but it will pay you back over time.

You can expect to save money on your overall wage bill, staff absences, injury payouts, and raw material wastage. With a reduction in costs and a projected rise in output, your profit margins will increase, and you’ll start to benefit from a return on your investment (ROI).

The key takeaway on tray-handling robots

If a bottleneck at the palletising stage is slowing down the rest of your production line and affecting output, then it might be time to think about investing in a tray-handling robot.

By cutting down on the number of people involved in material handling, you can reduce your labour bill, improve productivity, and increase your profit margin.

We are experienced in providing custom solutions across a range of industries, and we can help you too. For advice on taking the next steps, contact the automation experts at PALpack.