In manufacturing, efficiency is key to success. Improved efficiency results in greater productivity, less waste, fewer hours lost to downtime and lower costs. This is why automated technology such as sack-filling machines and palletisers is so valuable – these machines feature specialist gripping heads so rather than slow and labour-intensive manual handling of packages they can handle items with speed and precision.

Gripping heads explained

The specific gripping heads found on palletisers are designed to hold bags, sacks and packages securely, allowing them to be moved quickly and efficiently without any damage. Different gripping heads are available for handling different products and the most appropriate one will depend on the item’s shape, size, weight and handling requirements, such as how it needs to be picked up and laid down.

Common gripping heads may be vacuum operated, feature side clamps or magnets, or use a combination of all three.

Choosing the right robotic gripper

Where there is a flat top surface, such as on boxes, cartons and some bags, a vacuum gripper is often used, however, there are a number of reasons why at PALpack we prefer to use a physical mechanical gripper.

- Vacuum cups rely on good quality cardboard and if this changes, the porosity may alter causing many issues.

- It is not as easy to keep the case or pack stable and if the case rocks from side to side during the movement to the pallet, it can be placed wrongly on the pallet stack.

- Our tried and tested method ensures perfect placement every time, no matter how fast we move the product.

- Clients can pick up shrink-wrapped packs and cases with the same head.

All our palletisers are designed so that there are no change parts for different pack types.

Automated palletisers are designed for a wide range of environments and to handle many different products, from food and drink to pharmaceuticals to cosmetics. Several machines are available with different gripping heads for handling different products.

Cartesian palletisers

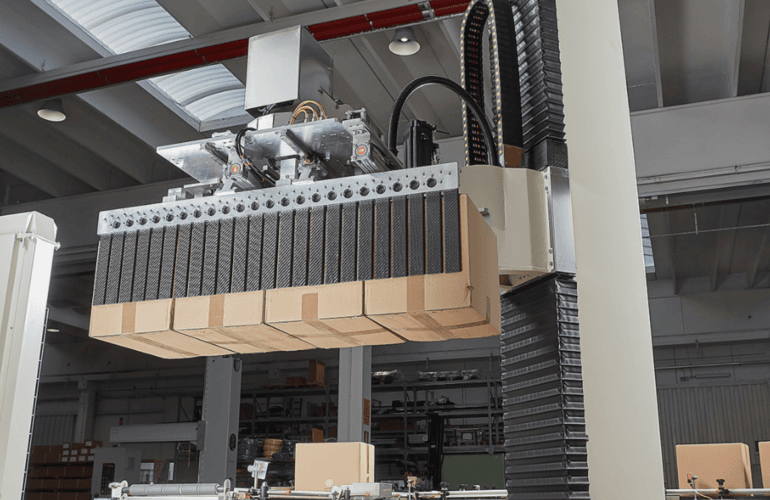

Robodue and Jolly are gantry-style Cartesian palletisers by word-leading manufacturer Lita and are used to pick and place items, often in complex pallet patterns. Several different gripping heads are available for handling different products, including side clamps and occasionally vacuum operated. Because of the different gripping heads, both can handle RSC cases and shrink-wrapped packs of varying sizes and Robodue (which is more heavy-duty and has a higher payload) can also manage jerry cans.

Robotic palletisers

Logico is a robotic palletiser also manufactured by Lita. Suitable for handling RSC cases, shrink wrapped packs, metal drums, bags, and sacks, Logico features a single arm with different gripping heads for different products being handled. They have the ability to insert pads between layers and handle empty pallets as well as move packages.

Sack palletisers

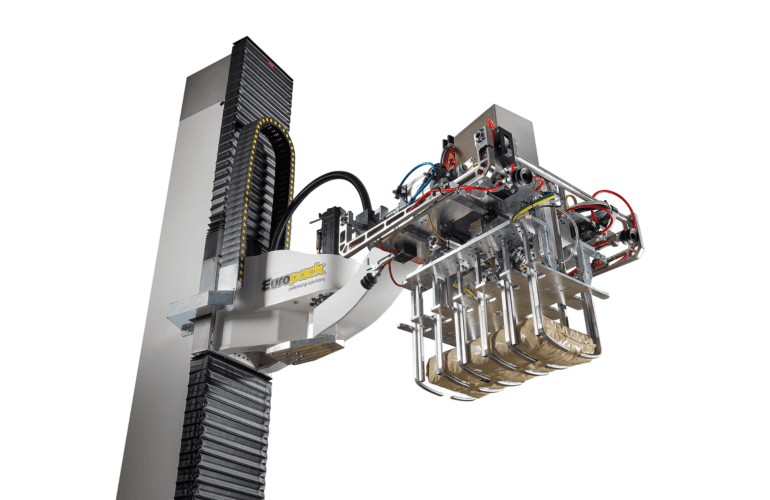

Different types of bags or sacks have different handling requirements and gripper heads can be designed accordingly. Europack’s rotating beam palletisers have a 360o rotating gripper head that can be changed to suit different packages, while combined heads can deal with more than one type of product.

Handling bags and sacks efficiently is essential for many industries. Using sack-filling and palletising technology along with specific gripping heads improves processes, saving time, reducing manual labour and helping manufacturers to improve their overall operations. Palpack can supply not only sack palletisers, but working with Europack’s partners, Vai, we can also supply VFFS sack filling machinery.