End-of-line automation refers to the technologies and systems used to automate the final stage of the production process – preparing, packing and palletising finished products for distribution – and is a critical part of any modern manufacturing operation.

Why choose end-of-line automation?

Adding end-of-line automation can enhance operations in a number of ways. From improving efficiency to helping to ensure compliance, the equipment and technology involved delivers several advantages:

- Increased efficiency – automated systems can handle repetitive tasks at high speeds, significantly increasing overall production efficiency.

- Cost savings – the increased productivity and reduced errors that come from automation deliver long-term cost savings. Plus, automating tasks such as packaging, labelling and palletising can reduce labour costs too.

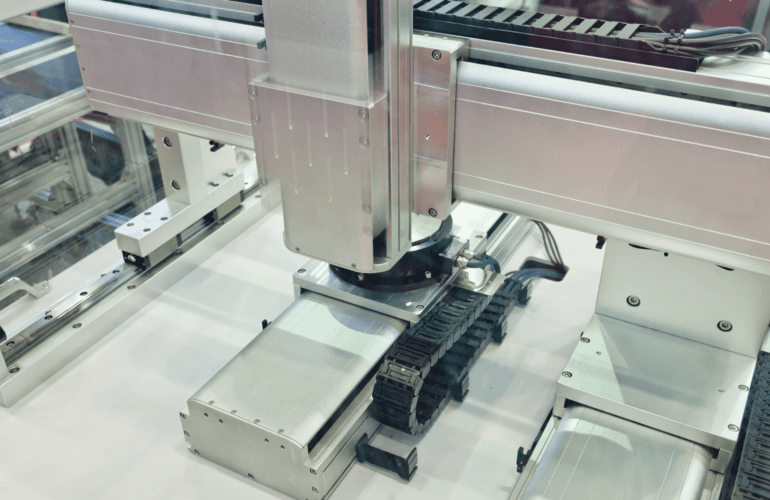

- Enhanced accuracy – automated systems deliver precision and consistency, reducing the risk of errors such as mislabelling or incorrect packaging. Add in advanced vision systems and sensors that can detect defects or inconsistencies in products and you can ensure only the highest quality items reach your customers.

- Improved safety – when machinery replaces human workers performing physically demanding and repetitive tasks, it minimises the risk of accident or injury.

- Flexibility and scalability – many end-of-line automation systems are designed to be flexible and easily adaptable to changes in product specifications or packaging requirements and can be scaled up quickly to meet market trends and demand.

- Compliance – ensuring that products are packaged and labelled correctly to meet regulatory requirements and standards reduces the risk of compliance-related issues and associated penalties.

What do I need to implement end-of-line automation?

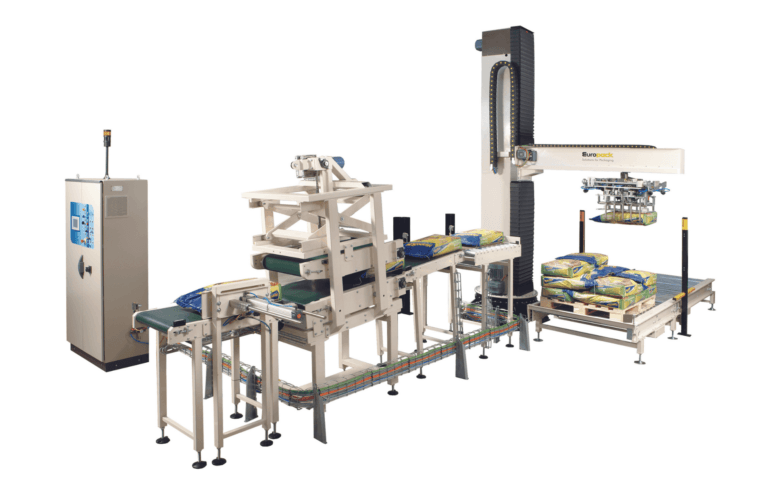

The equipment required varies depending on the application, type of packaging and production levels but commonly consists of palletisers and case packers. However, it can be much more elaborate and include:

- Conveyor systems

- Cartoning machines

- Automated sack-filling machines

- Bag closing machines

- Vision systems and sensors

Any number of these devices can be incorporated into manufacturing operations to eliminate bottlenecks and improve efficiency and the smart software used enables communication between different components.

How does end-of-line automation work?

Manufacturers across various sectors increasingly adopt end-of-line automation to boost productivity, ensure product quality and streamline their operations. Let’s look at three sectors in more detail.

1. Food manufacturers

For food manufacturers, end-of-line automation ensures the safe and efficient packaging of perishable goods by minimising risk of contamination and enhancing overall product consistency. Sensors and x-rays are increasingly being used to detect the presence of foreign materials whilst vision systems inspect labels to ensure expiry dates, batch codes and other information is clear and readable.

2. Beverage manufacturers

Beverage manufacturers typically use end-of-line automation to speed up the packaging and palletising of bottled products. Automated conveyor systems and robotic arms handle items quickly and precisely, minimising the chances of breakage or spillage.

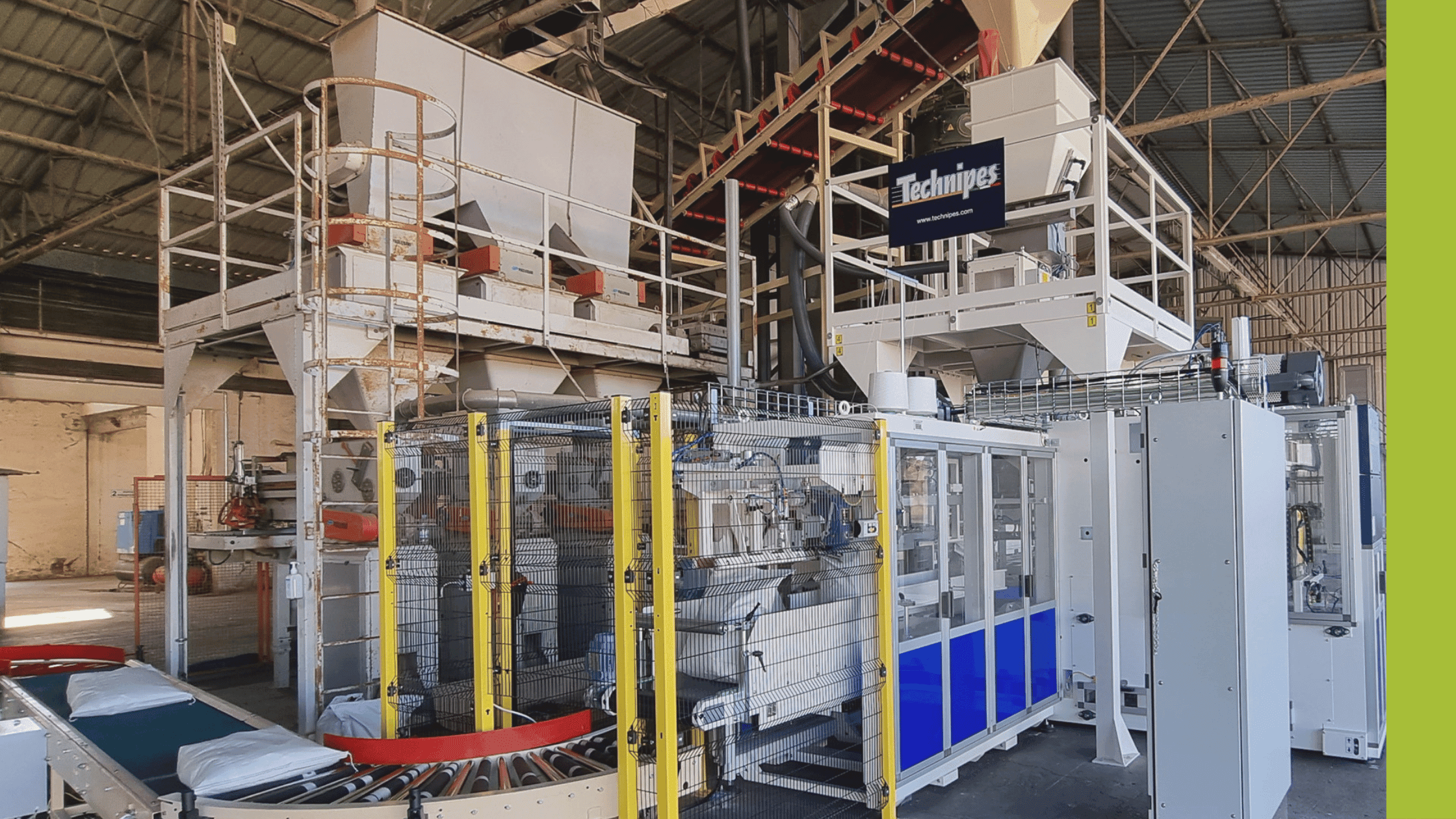

3. Aggregate manufacturers

Automating the repetitive and gruelling tasks of packaging and palletising heavy, bulk materials such as sand, gravel or cement reduces the risk of injury to workers and speeds up the process. Automated systems such as single-weigh conveyors make checking the weight of packages faster and easier, improving consistency and reducing wastage.

Using end-of-line automation to boost output

We’ve explained how end-of-line automation can help to improve productivity and boost output but the advantages extend beyond operational benefits. With the right equipment, in the correct position, it’s possible to positively impact safety, sustainability, staff morale and many of the other elements that contribute to overall business success.