Food safety is a critical part of food manufacturing and proper packaging is integral to complying with the many relevant rules and regulations. From preserving freshness to detailing ingredients, using the correct packaging helps to ensure the safety and quality of products from the production line until they reach the customer.

The importance of packaging in food safety

Packaging and food hygiene go hand in hand. To remain safe to eat, food must be protected from chemicals and toxins, such as bacteria and viruses, that can spoil food and cause illness. The right packaging acts as a barrier, preventing this and other kinds of contamination and preserving freshness. Perishable foods such as dairy or meat may need to be shielded from exposure to air, moisture and light to prevent deterioration.

In addition to protecting goods, packaging and labels provide important information to customers regarding ingredients, nutrition and allergens. Barcodes and batch numbers store further details that can be used to identify products in the case of a manufacturing issue or recall.

Different types of food packaging

Food packaging can take many forms and each brings different benefits.

- Plastic packaging is versatile, lightweight and cost-effective. Suitable for a range of food products due to its ability to be moulded into different shapes, it is especially good for items customers want to see clearly. Plastic packaging can include tamper-evident seals and oxygen barriers to prevent food spoiling.

- Glass is strong and impermeable, providing a durable yet transparent barrier that can also include tamper-evident lids. Because it is an inert and non-reactive material, it won’t alter the taste or quality of food, however it is heavy to transport, which can increase costs.

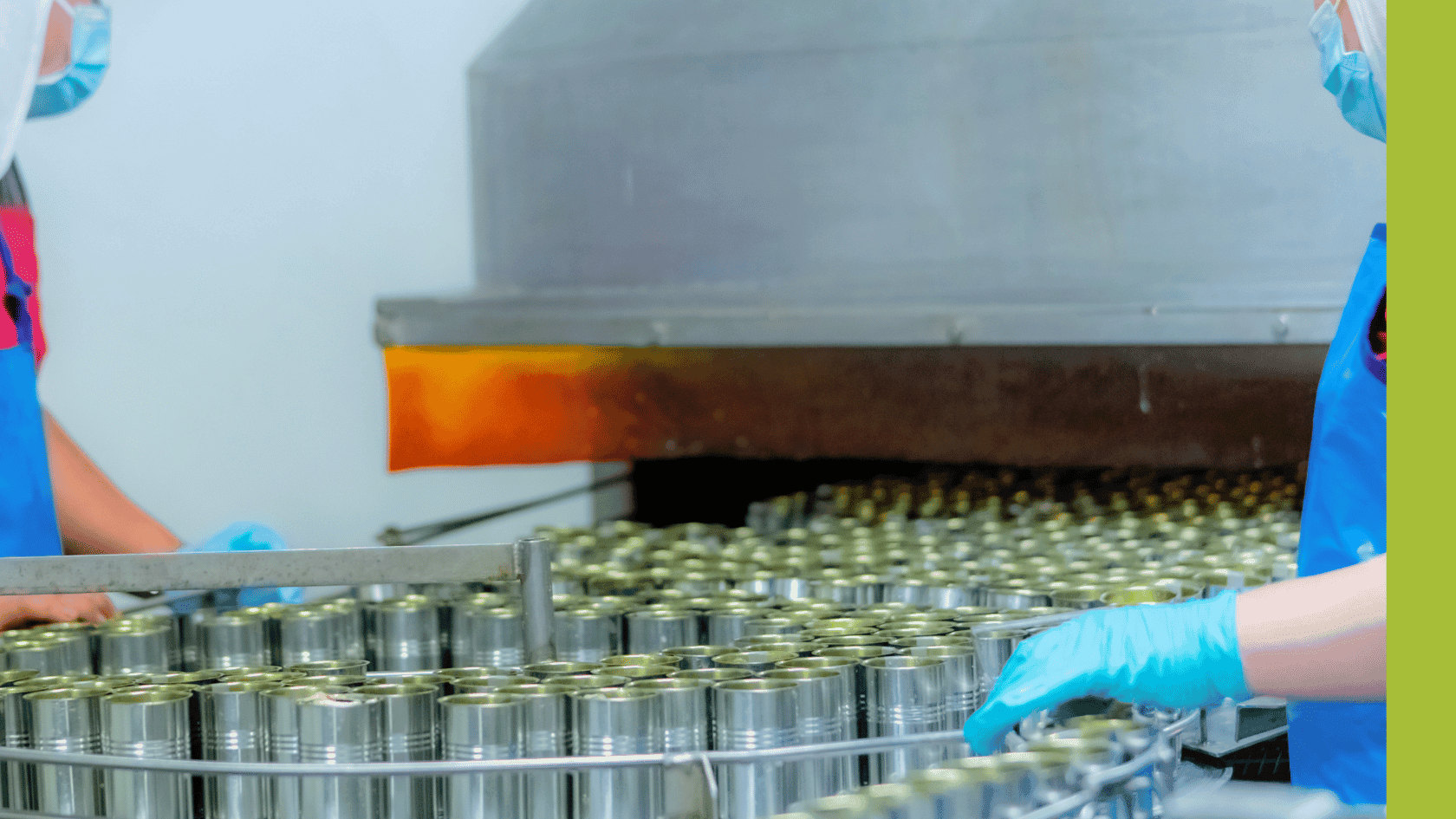

- Metal packaging is ideal for preserving food over long periods due to its strength and durability. Tin cans provide an effective barrier against light and oxygen, and because they are airtight, microbes are unable to grow.

- Paper and cardboard are a sustainable choice, often used for dry goods that need to breathe. Bags and boxes are easy to print and label, and can be coated with food-grade materials to provide a more substantial barrier – although be aware this may remove some of the environmental benefits.

An overview of UK food packaging regulations

In the UK, best practice dictates that food packaging must adhere to the range of regulations and standards in place to ensure customer safety and quality control throughout the supply chain. These include Food Standards Agency (FSA) regulations as well as relevant EU regulations. The Food Safety Act 1990 requires all food businesses to “not treat food in any way which means it would be damaging to the health of people eating it”, and The Materials and Articles in Contact with Food Regulations 2012 implements a number of EU rules. Within this, the Framework Regulation EC 1935/2004 requires that materials in contact with food be safe and not compromise food quality. Food packaging should be marked with the food safe logo or the words “for food contact”.

Introducing packaging machinery

We already know that automated machinery can help ensure quality control and consistency, but it has a role to play in food safety too. By streamlining the packaging process and enhancing precision the chance of contamination due to human error is reduced, containers are sealed effectively and moved efficiently, without damage to the packaging or its contents.

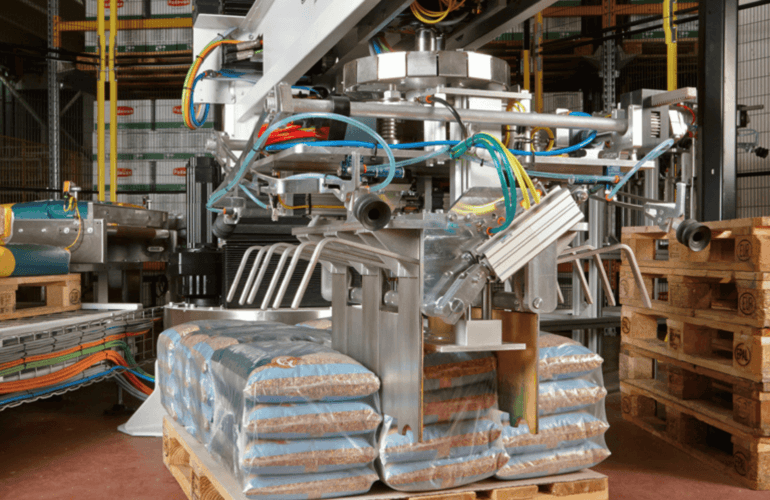

Sack-filling machines automate the filling of bags and sacks, reducing the need for human handling and ensuring consistent quantities are packed every time. Many include dust control systems to minimise the particulates released into the air and reduce the chance of cross-contamination whilst heat-sealing or stitching packages closed preserves the safety and quality of the foodstuffs within.

The food and drink industry is the UK’s largest manufacturing sector and introducing automation helps to keep it running smoothly, profitably and safely. Let’s get started! Get in touch.