From reducing labour costs to increasing productivity, the role of automation in manufacturing is clear. But finding the right equipment for the job can be a challenge.

Enter, LITA Palletising Systems, expert in material handling since 1962. Known for its precision-engineered palletisers, depalletisers and handling solutions, the company’s comprehensive ranges integrate into the production line seamlessly, optimising workflows and boosting efficiency.

About LITA Palletising Systems

Family-owned and with a strong focus on quality engineering and tailored automation, LITA works with manufacturers in diverse sectors, including food and beverage, pharmaceuticals, and consumer goods. Solutions can be tailored for both large-scale and compact spaces, and the equipment is designed to handle everything from shrink-wrapped packs to delicate containers, ensuring a smooth, automated flow of goods from start to finish.

Why choose a LITA palletiser?

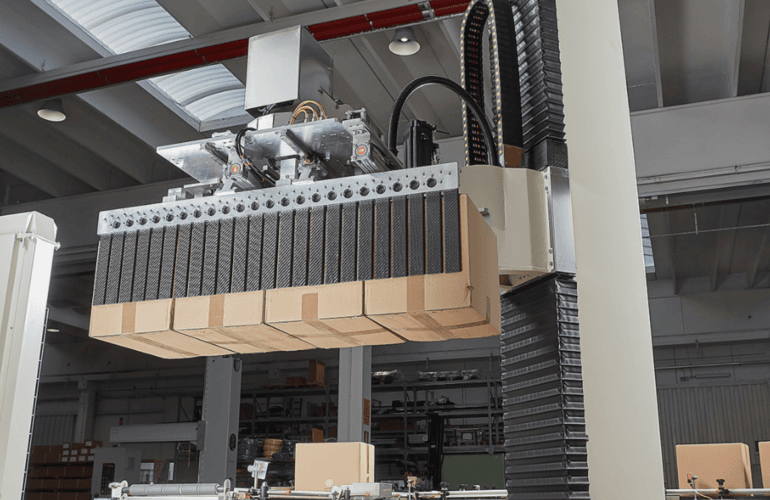

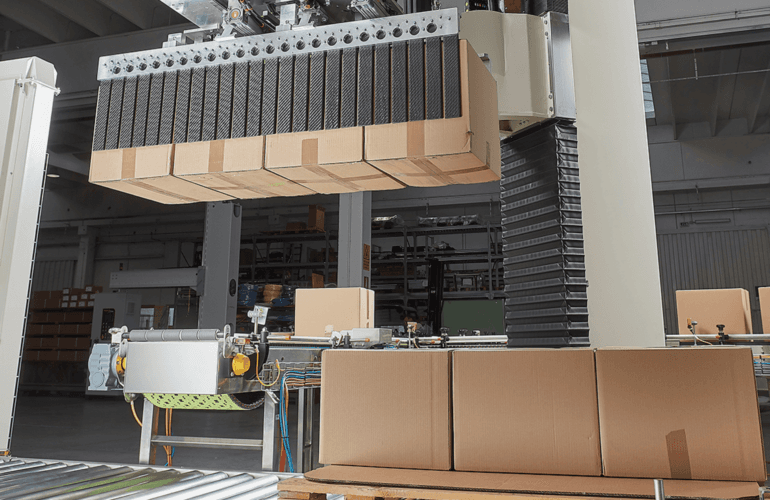

LITA specialises in conventional medium to high-paced palletisers, including cartesian, layer and robotic palletisers, all of which are known for their high levels of precision and flexibility and user-friendly design. They can process a wide range of packaging types which allows for consistent throughput in industries where packaging requirements may frequently change or in operations handling multiple product lines.

- The Alto layer palletiser is designed to manage different packaging formats and the configuration options allow for customised pallet patterns too. It is equipped with pallet conveyors, an empty pallet destacker and an optional device for inserting pads between layers for added stability. Especially suitable for industries with high production volumes, the system can process up to 42 packs per minute with a single infeed, and up to 65 packs per minute with the twin infeed option.

- LITA’s Jolly palletiser is a compact, space-saving cartesian palletiser, which can reliably handle a variety of packaging types thanks to its multiple gripper heads. Its lightweight aluminium axis carriages make it fast, energy-efficient and highly agile. The basic version can handle up to 8 cycles per minute, while a high-speed version can achieve up to 12 cycles per minute.

Other LITA systems available

LITA Palletising Systems is known not only for its palletising machines but also for its innovative depalletisers and material handling solutions.

The Metro depalletiser is one of six different depalletisers offered by the manufacturer and is an automatic sweep-off type system, designed to remove cylindrical and rectangular glass and PET bottles, glass jars, and cans from pallets efficiently and precisely. With an output of up to 140 layers per hour, it is a powerful solution for high-volume depalletising.

See LITA’s Metro depalletiser in action

The palletising and depalletising equipment is complemented by a range of additional handling systems which can be integrated to ensure seamless movement of products along the production line. The conveyors and other systems include:

- Bottle conveyors to handle glass and PET bottles without applying pressure, reducing the risk of breakage.

- Accumulation conveyors, pack and case conveyors, pack dividers and case overturners, which are ideal for handling grouped or boxed products, allowing them to be positioned and then moved along production lines.

- Spiral belt and continuous or reciprocating vertical elevators for the movement of products between different heights.

- Roller, chain, and turntable options, plus full pallet linear shuttle cars and vertical lifts, which enable the efficient transport, turning and lifting of full pallets in larger warehouses or production sites.

Together with LITA’s palletisers and depalletisers, these systems reduce the need for manual intervention, improving the flow of products and making the entire process more efficient.

Whether you’re looking for a complete system or standalone solutions, LITA offers the flexibility, reliability and scalability to meet your needs.