Most food manufacturing and packaging processes can now be automated. Employing robotics for the secondary packaging process is the last link in the chain.

In all food manufacturing, food items are placed into primary packaging and secondary packaging – the container or packet that holds the food item itself, and then the exterior packaging that protects the wrappers or containers for transportation and shelf-stacking.

Secondary packaging

Exterior packaging can include:

- Cases (boxes)

- Shrink wrap

- Trays with shrink wrap

- Loose trays (no shrink wrap)

Loose trays are becoming more popular with supermarkets. In the news last year, the government was pushing them to get rid of single-use packaging totally. Loose trays minimise plastic usage, and speed up de-palletisation at the other end, as they can just be taken straight off a pallet and placed directly onto the supermarket shelf.

Palletisers

Stacking loose trays is just one of the palletisation processes PALpack can automate.

Around 75% of PALpack’s work is for the food industry. A lot of food factory processes get automated before the secondary packaging stage. It usually starts with the cooking process, then the primary packaging.

Often, we find that the last step in automating the manufacturing and packaging process is palletising – and by this time, it often seems like there’s no space left on the floor for the machinery.

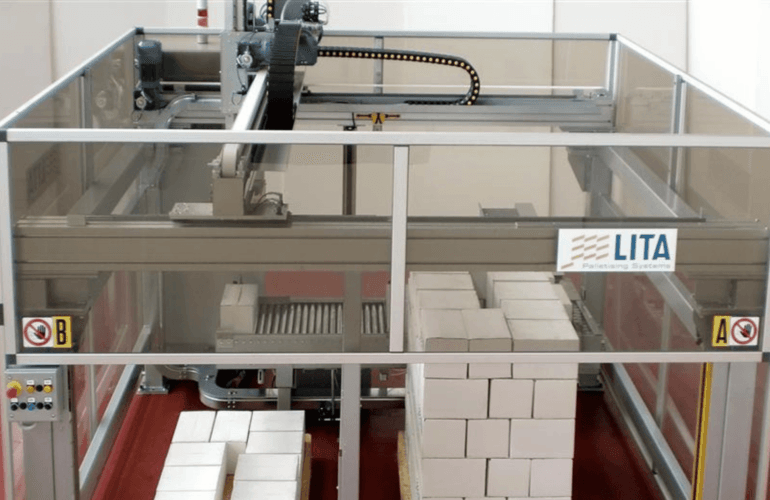

We’ve carefully chosen palletisers for our range that fit into a small footprint, for exactly this reason. The video below shows a high-speed Lita machine palletising shelf-ready packs.

De-palletisers

Similarly, when companies buy pallets of empty containers to be filled, they need to be taken off the pallet and fed into the system – another manual process that can be alleviated with robotics.

The video below shows an automatic Lita sweep-off de-palletiser in action.