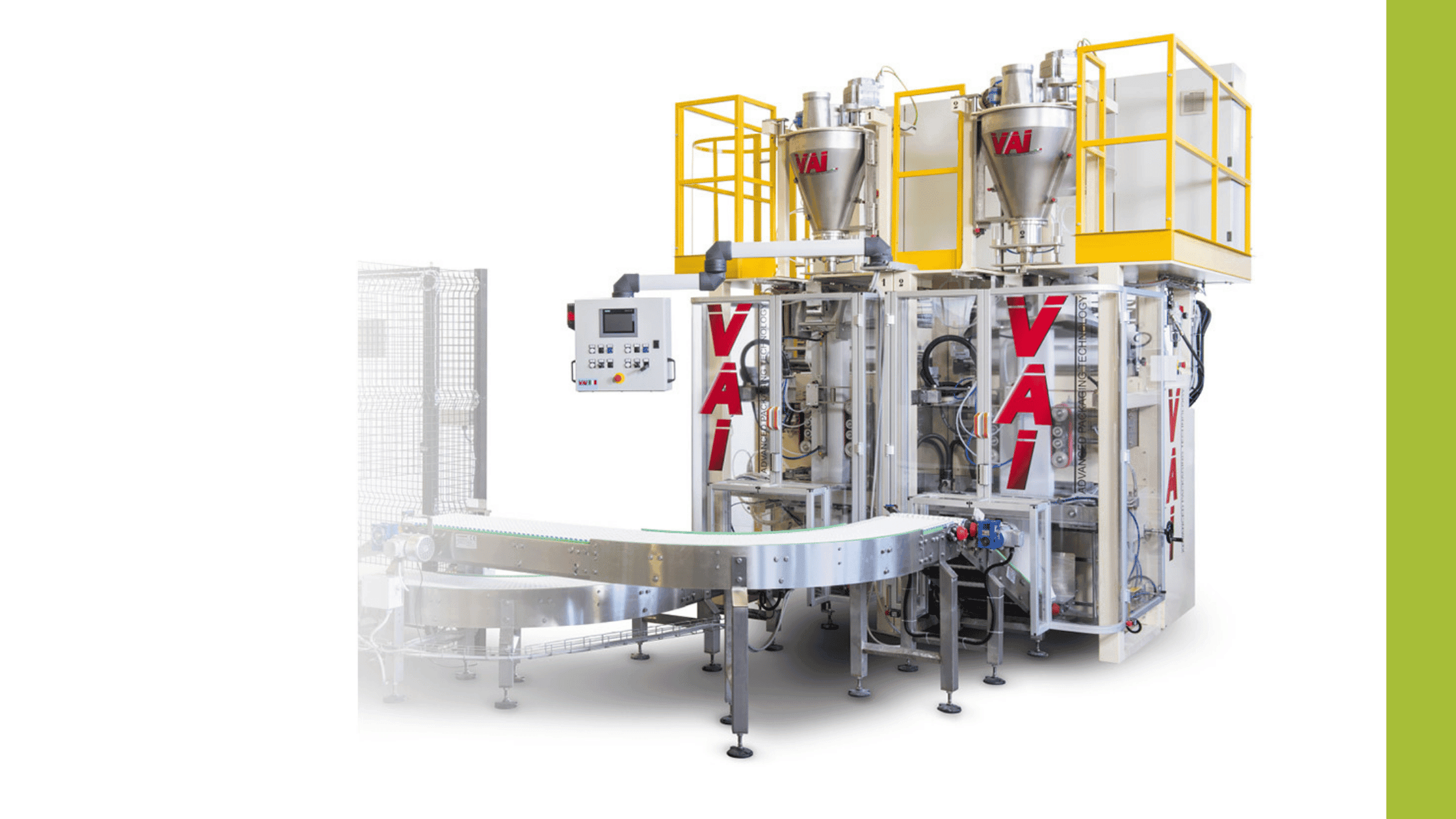

When it comes to sack filling there is a lot to gain from replacing manpower with machinery. In this blog, we look at the vertical form fill and seal (VFFS) from Italian manufacturer, VAI, and ask, what are the benefits of using a sack filling machine?

What is a sack filling machine?

Sack filling machines can fill, weigh, and seal bags at high speed – a job that would otherwise take a long time to complete manually. These self-optimising machines can handle a variety of products, from powder to pellets, and even pasta.

You’ll find them used in a range of industries, including:

- food (e.g., flour, sugar, salt, pasta, biscuits)

- building and construction

- pet food

- aggregates and grain

- chemicals

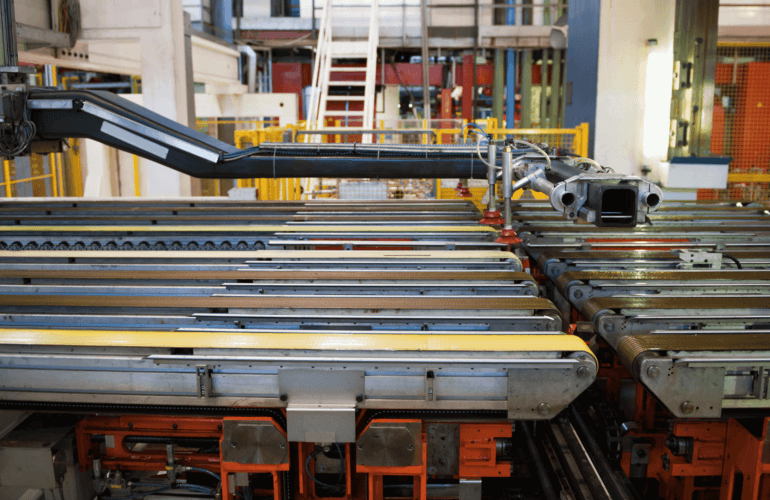

They work by making the bags then weighing the product (or ‘dosing’), and finally, filling the bag, sealing it closed, and delivering it to an out-feed conveyor. You can see how it works with bags of small pasta in this video of a sack filling machine in action.

For a complete end-to-end solution, it’s also possible to combine sack filling with other automated devices, such as sack palletisers and automated guided vehicles (AGVs).

Vertical form fill and seal (VFFS) machine

The high-speed ‘V5/10 Special’ from VAI can fill up to 1100 bags per hour, and what’s more its double weighing system guarantees accurately filled bags every time.

The intelligent product level sensors recognise the characteristics of each product, so no bags are half-filled. And there is no wasted raw material because the machine uses a roll of flat PE bags which are made specifically to fit around the product.

VAI has been manufacturing sack filling machines for over 40 years, and their experience in the industry has earned them a reputation for reliability and quality.

The ‘V5/10 Special’ is designed to be used with pellet and granular products, but VAI’s wide product portfolio also includes machines with different capabilities, from those that deal with small bags of pasta up to special units for industrial-sized packaging.

The benefits of a sack filling machine

When you introduce automated sack filling into your production line, you can expect to benefit from improved efficiency, greater accuracy, and reduced labour costs.

- Improved efficiency

Sack filling is time-consuming, but with the help of a machine, you can speed-up the process, and by filling more bags per hour, you can increase your output significantly.

- Greater accuracy

These machines are built with accuracy and precision in mind, making it easier to conform to regulatory standards in your industry and meet your customers’ expectations.

What’s more, sack filling machines make fewer mistakes and when you compare that to how much material is wasted during manual filling, it represents a cost-saving.

- Reduced labour

By automating the sack filling process, you no longer need the same number of personnel, which will save you money on your overall labour bill. This is an opportunity to reposition your most skilled workers somewhere else in the business.

Sack filling machines – the bottom line

Sack filling is a time-consuming, repetitive, manual task that can be vastly upgraded with automation. By removing the human element and replacing it with a machine, you can benefit from reduced costs, improved profitability, and a more satisfied workforce.

The speed and accuracy of these machines will continue to make them a firm favourite with managers looking to automate some of the ‘pinch points’ in their production line.