The skills shortage in manufacturing is well-documented and it’s not only causing significant economic impact but also limiting the industry’s potential for growth and innovation. According to the UK government, 168,000 new workers are needed to enter the manufacturing sector annually up to 2024 in order to meet demand.

It’s a complex issue, resulting from the combined impact of an ageing workforce, less education and training opportunities, and a lack of interest in the jobs on offer – but there are things that can be done to address the problem. Investing in automation is one such solution and in this blog, we look at how introducing robots and cobots to your operation can help minimise the impact of the skills shortage.

1. Streamline processes

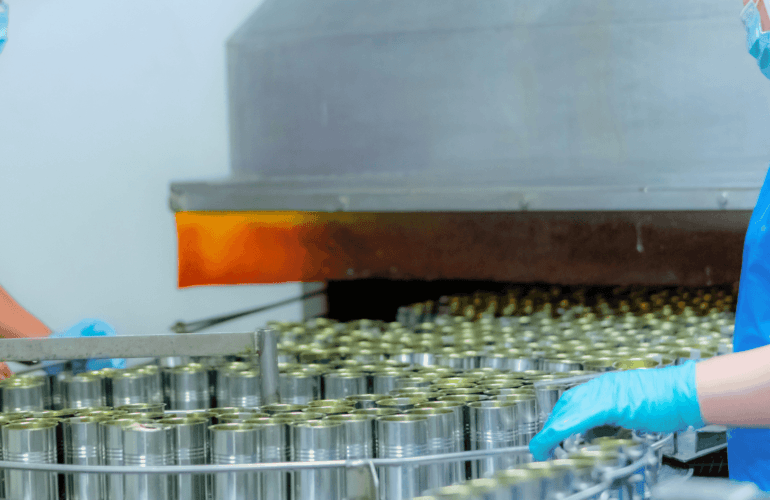

Some of the hardest vacancies to fill are the most critical; the repetitive or physically demanding tasks of loading and unloading pallets may be boring but they keep the production line moving. Therefore, it makes sense to automate these roles in order to prevent bottlenecks and maintain efficiency. Palletisers and depalletisers can sort and transfer packages automatically, often much faster and more accurately than human operatives. Layer palletisers for example have a production speed of up to 60 packs per minute.

2. Focus on higher-level tasks

With machines taking on repetitive, physically demanding and hazardous tasks, workers are freed up to focus on more complex and creative jobs that require human skills. Allocating roles that include problem-solving, critical thinking, and decision-making to employees not only adds value to the business but motivates workers, improving wellbeing and morale and, as a result, staff retention. Combined, this gives manufacturers a competitive advantage, especially as the industry struggles to find and retain talent.

3. Improved quality

Automation can also help to improve the quality of work and reduce the risk of errors and wastage. With robots and other machines performing tasks with high accuracy and consistency, the need for someone to rework and conduct manual inspections can be minimized. This can not only save time and resources but also improve product quality and customer satisfaction.

4. Bridge the gap

Introducing automation and the associated technology can also help to bridge the skills gap by attracting younger generations into manufacturing. As robotics advances to incorporate technologies such as artificial intelligence and machine learning, it begins to appeal more to younger digital natives and can provide workers with additional training and upskilling opportunities.

5. Working together

Automation doesn’t just help fill open manufacturing jobs. Industrial cobots can also be used alongside existing roles, aiding with repetitive or dangerous tasks to improve product quality and consistency and increase overall productivity. Cobots can work in the same factory space as humans with fewer safety concerns and are often easy to use, reducing the need for highly skilled or technical operators.

Innovative solutions

There’s no doubt the skills shortage in manufacturing is a significant challenge but it’s one that can be overcome with the right tools and strategies. By embracing automation technologies, the manufacturing industry can unlock new opportunities for growth and innovation and ensure a skilled and talented workforce for the future.