The wellbeing of employees in the workplace is of utmost importance and as the start of October marks Backcare Awareness Week, it’s a good time to take a closer look at how automated equipment such as depalletiser machines can help to minimise workplace injuries, especially to the back.

Back injuries are among the most prevalent and debilitating types of workplace injuries: it’s estimated that 477,000 UK workers are suffering from a work-related musculoskeletal disorder. They frequently result from lifting, carrying, and manipulating heavy objects – often repeatedly – which are common tasks on the manufacturing floor. Back pain can range from mild discomfort to severe, chronic conditions, affecting the quality of life of workers and the productivity of businesses. Figures from the HSE show 36.8 million working days were lost due to work-related illness and workplace injury in 2020/21.

Types of injury and the causes

Two of the most commonly seen workplace injuries are repetitive strain injuries (RSIs), which affect muscles, nerves and tendons, mainly in the upper body, and musculoskeletal disorders, which are injuries to soft body tissues including muscles, nerves, tendons, ligaments, joints, cartilage and spinal discs.

Causes may include:

- Moving and lifting boxes on and off racks

- Gripping bulky items that may not have handles

- Bending and twisting to lift heavy materials

- Twisting and reaching overhead to get materials from racks and bins

- Reaching down or stopping to load and unload boxes

- Pushing or pulling heavy objects

- Using excess force

How can automation help?

Automatic handling systems eliminate the need for heavy lifting and minimise the awkward bending and stretching movements that can strain the back, helping to reduce injuries and promote a safer working environment.

Depending on the types of injuries workers are sustaining, equipment such as palletisers, depalletisers and sack-filling machines may all be beneficial.

- Automatic palletisers stack and load goods onto pallets quickly and efficiently, removing the need for items to be moved by hand. They can handle heavy packages and move consistently, reducing the risk of injuries caused by repetitive motion or sudden exertion.

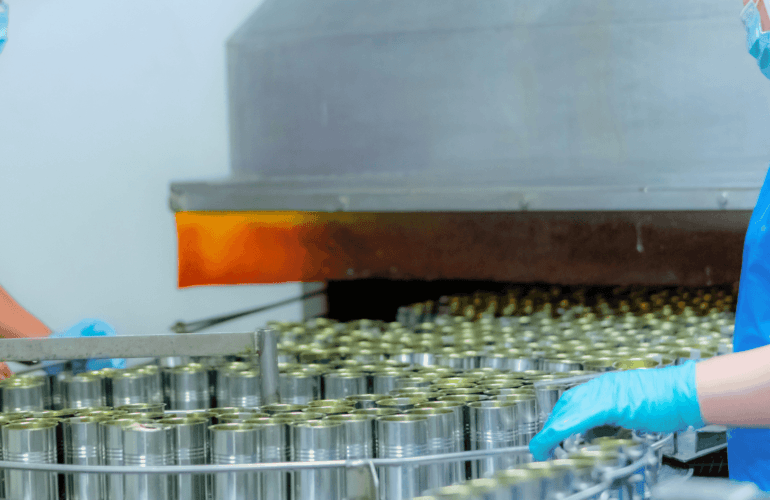

- Automatic depalletisers unload packages from pallets efficiently, transferring them onto the production line. Goods of all types are moved without the need for manual intervention, reducing the risk of accidents and allowing workers to be deployed on more interesting tasks.

- Sack-filling machines efficiently fill bags with bulk materials from foodstuffs to aggregates, reducing the need for employees to lift and handle heavy bags manually. Dust containment systems also protect workers from any respiratory conditions caused by dust and debris generated during the filling process.

Enhancing workplace safety

The integration of automatic handling systems extends beyond reducing back injuries alone. It also fosters a culture of safety and wellbeing in the workplace by:

- Boosting efficiency. Employees can focus on tasks that require human skills and judgement – and deliver higher value – rather than repetitive, injury-prone activities.

- Minimising human error. Automation reduces the risk of accidents caused by human error, improving overall workplace safety.

- Enhancing job satisfaction. A safer, less monotonous work environment contributes to higher job satisfaction, greater motivation and better mental health amongst employees, improving employee retention and further benefiting businesses in the long run.