For decades now, the manufacturing industry has faced labour shortages. Since 2010, the number of UK manufacturing jobs has decreased dramatically, yet there are still currently around 61,000 vacant positions.

With operative numbers already in decline due to an ageing workforce and lack of skills, Brexit exacerbated the problem. A 2024 report estimated that the UK economy has 1.8 million fewer jobs overall as a result, making the challenge of maintaining and growing manufacturing employment even more difficult. In fact, 75% of manufacturers say skills shortages are their biggest barriers to growth.

However, there is hope: automation presents a promising solution to bridge this gap and ensure the sector remains competitive.

The impact of Brexit on labour supply

The manufacturing industry has historically relied on a steady influx of skilled and semi-skilled workers from the European Union, especially in food and drink manufacturing, but with Brexit came new immigration policies and restrictions, making it harder for businesses to recruit from abroad. Couple this with increased costs caused by trade disruptions, increased tariffs and the economic effects of the pandemic, and many companies find they are unable to meet demand and are up against delayed orders, reduced output and increased operating costs.

The planned increase of the minimum wage to £12.21 in April will make the UK the third most expensive country in Europe for labour, just slightly below Germany. And because rules state that when UK businesses export to the EU, buyers in EU countries are responsible for paying VAT and any applicable duties, UK products and services are becoming less competitive in the EU market.

Together, these factors raise the overall cost of doing business in the UK, leaving many companies struggling to remain competitive.

How automation can bridge the skills gap

Automation refers to the use of advanced technologies, such as robotics and machine learning, to automatically perform tasks traditionally done manually by human operatives. By introducing automation into their production lines, businesses can reduce the effects of labour shortages while improving efficiency and productivity.

Automation brings a number of benefits:

1. Increased productivity

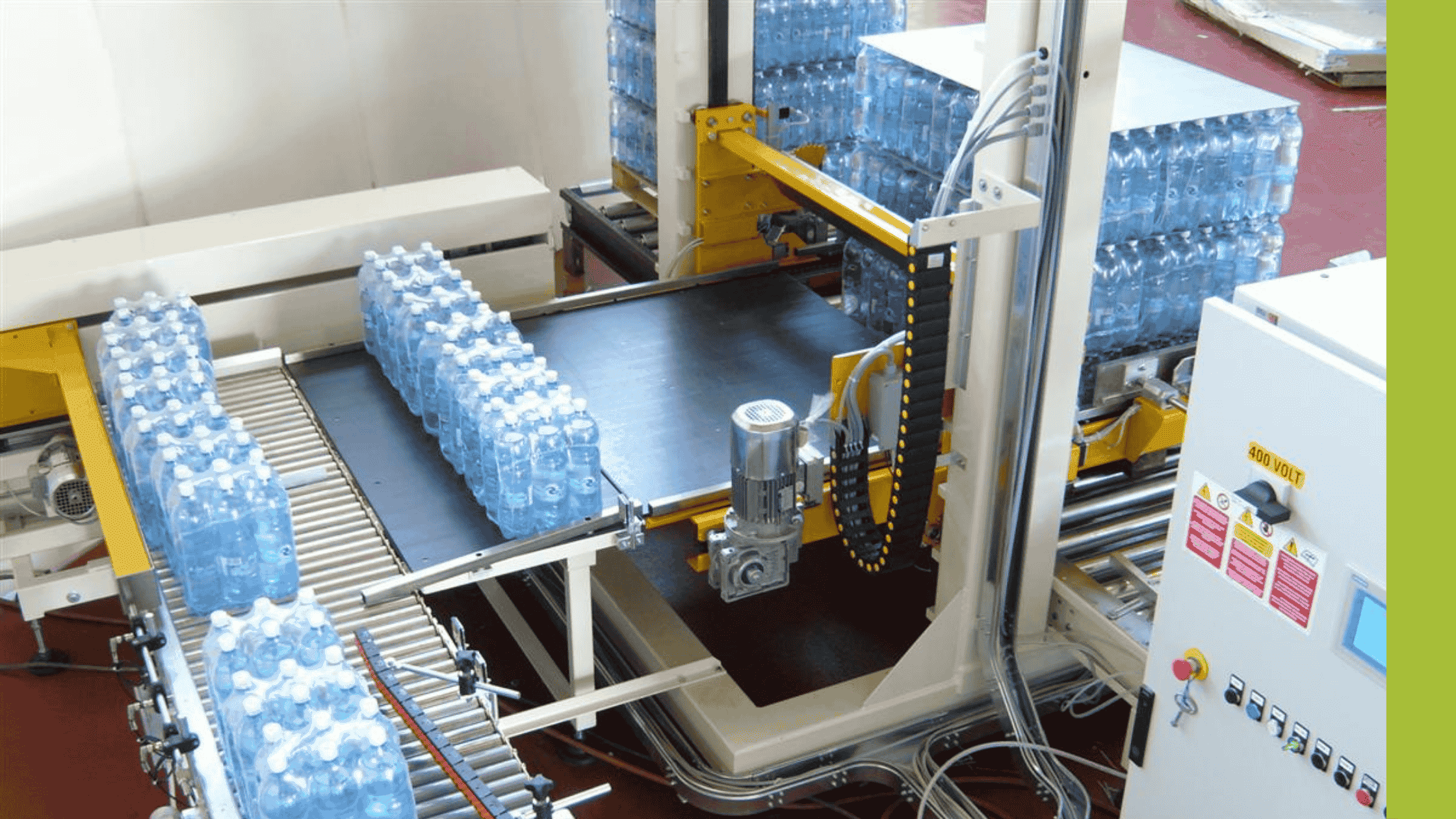

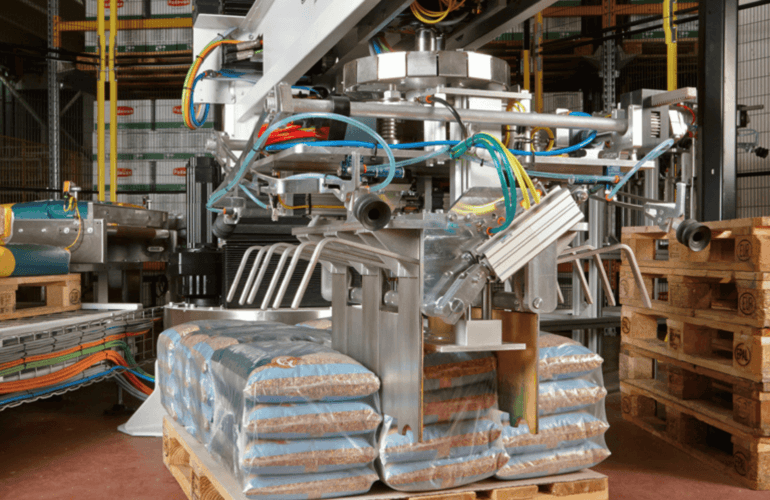

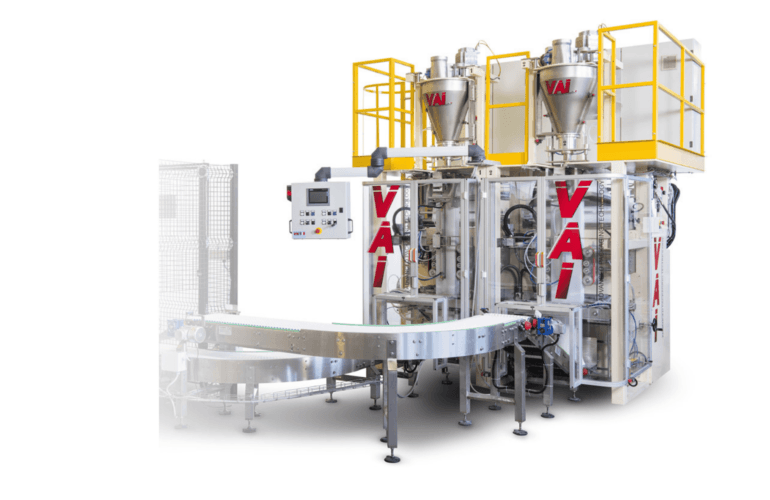

Automated systems work around the clock without the need for breaks, shifts holidays or sick leave, enabling manufacturers to meet higher production targets. Machines like palletisers and sack-filling machines can handle repetitive and physically demanding tasks precisely and consistently, so output can be guaranteed.

2. Enhanced quality control

Systems can be programmed to perform the same tasks extremely accurately, reducing wastage on the production line and costly mistakes or recalls with the finished product. Better product quality and reliability also increase customer satisfaction.

3. Cost efficiency

Although there is an initial investment required the long-term return on investment offered by automation can be significant. Many have energy-saving features to reduce energy use and costs, and the flexibility allows for production to be scaled up without the need to pay for additional temporary labour at busy times.

4. Addressing skills shortages

With fewer workers available or willing to take on entry-level or manual roles, automation can fill the gap by taking over these positions. This allows human employees to be trained and upskilled to manage the systems or work elsewhere in the business. This creates higher-value jobs and helps drive the shift to a more technology-driven environment.

Overcoming barriers to automation

Despite its benefits, the adoption of automation in manufacturing is not without challenges. Common obstacles include lack of space, cost constraints, integration issues and the disruption of installation. The good news is that all of these are easily overcome with advance planning and the right partner.

We’ll work with you to conduct a thorough cost-benefit analysis, help you find the right equipment for your operation and ensure that installation is quick and easy.

Automation is not just a response to labour shortages but an opportunity to future-proof UK manufacturing industry for the long term. By embracing advanced technologies, manufacturers can go a long way to solving skills shortages, helping them to remain competitive and grow.