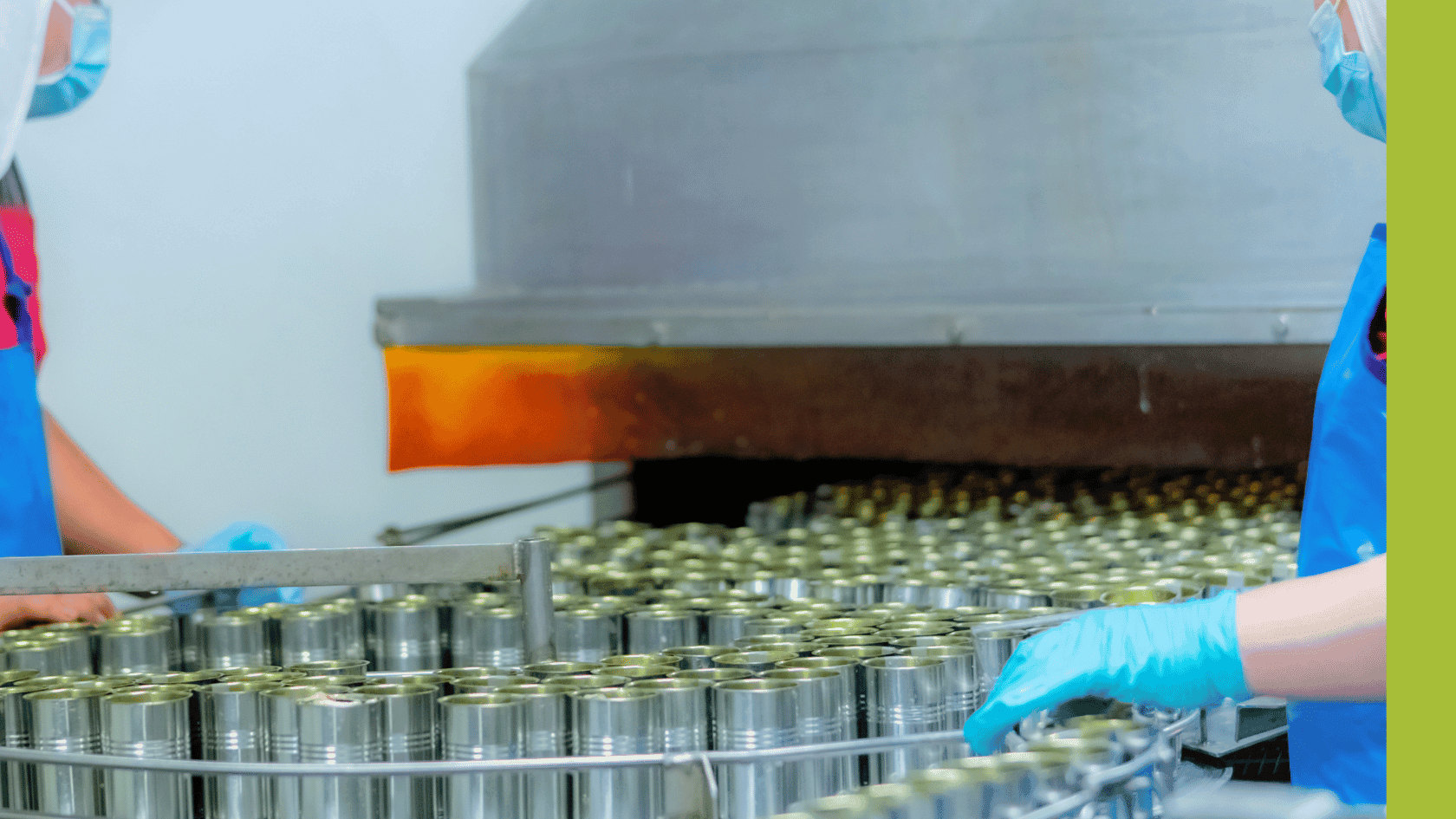

Ensuring food safety through proper packaging

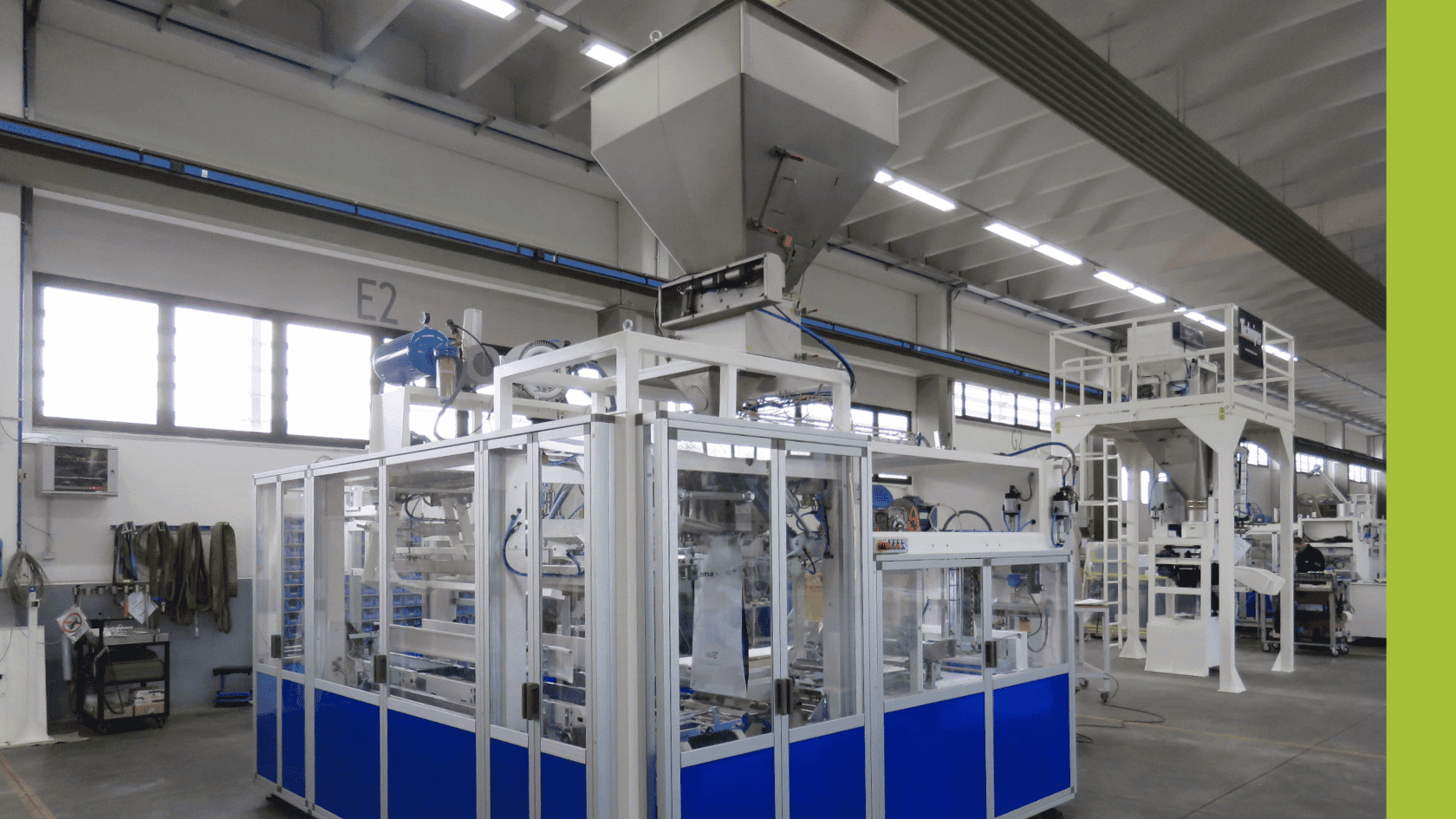

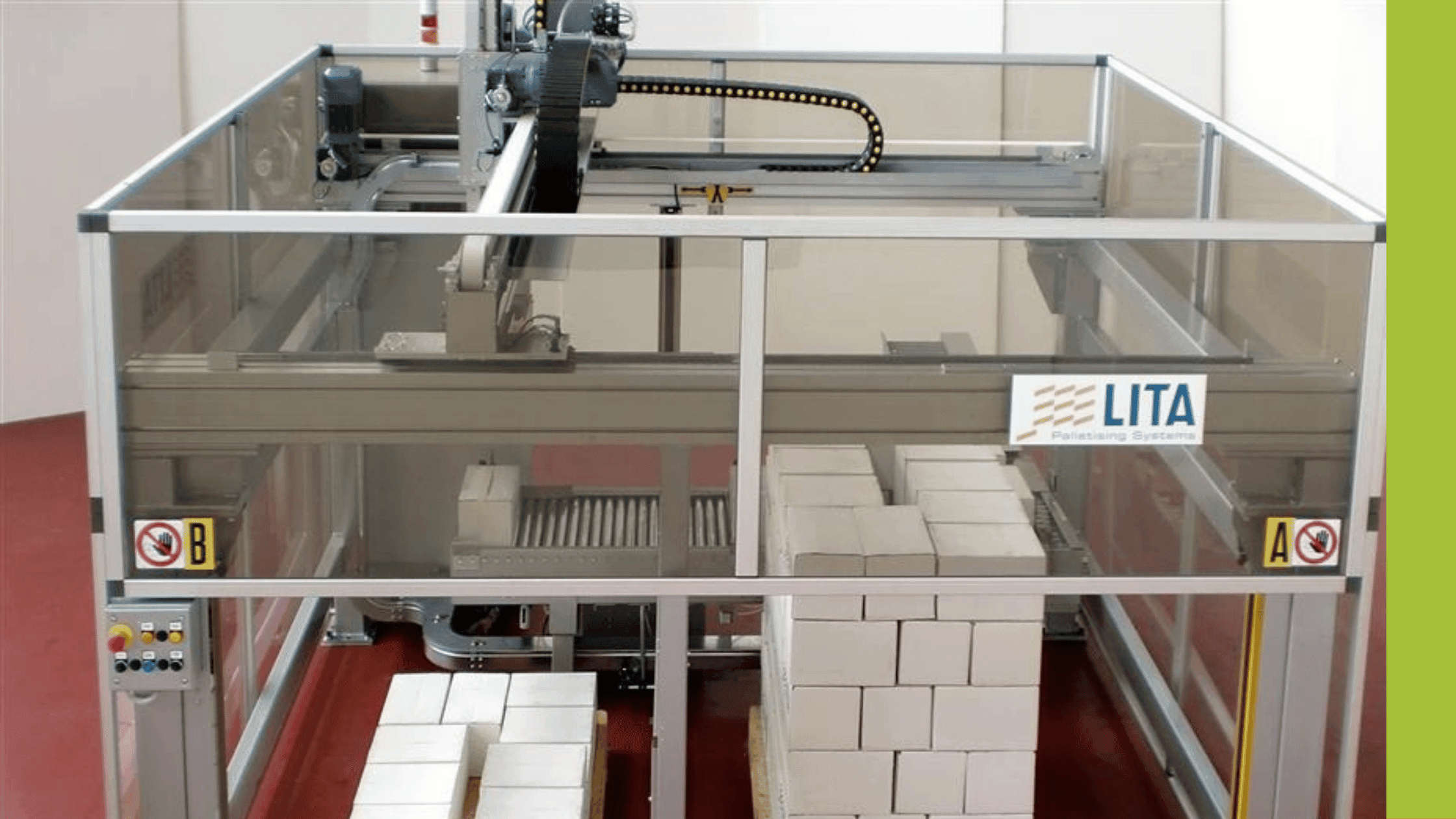

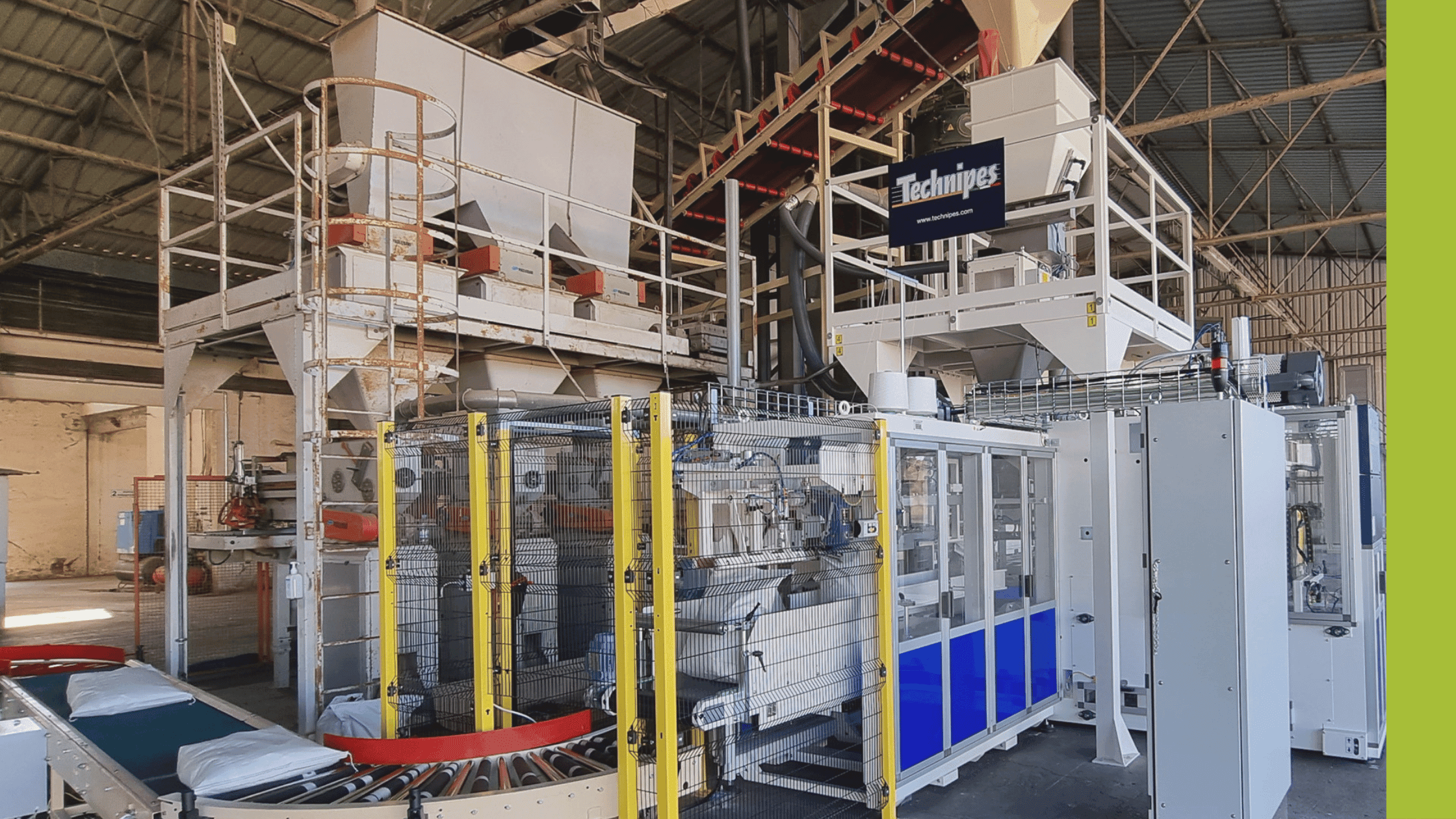

Food safety is a critical part of food manufacturing and proper packaging is integral to complying with the many relevant rules and regulations. From preserving freshness to detailing ingredients, using the correct packaging helps to ensure the safety and quality of products from the production line until they reach the customer.