There can be many steps to moving your product through the manufacturing process. How does automation streamline this manual process, while maintaining control and protecting the goods?

Manufacturers generally have a similar flow on the shop floor:

- Materials de-palletisation and unpacking

- Manufacturing process

- Packing

- Moving or handling goods

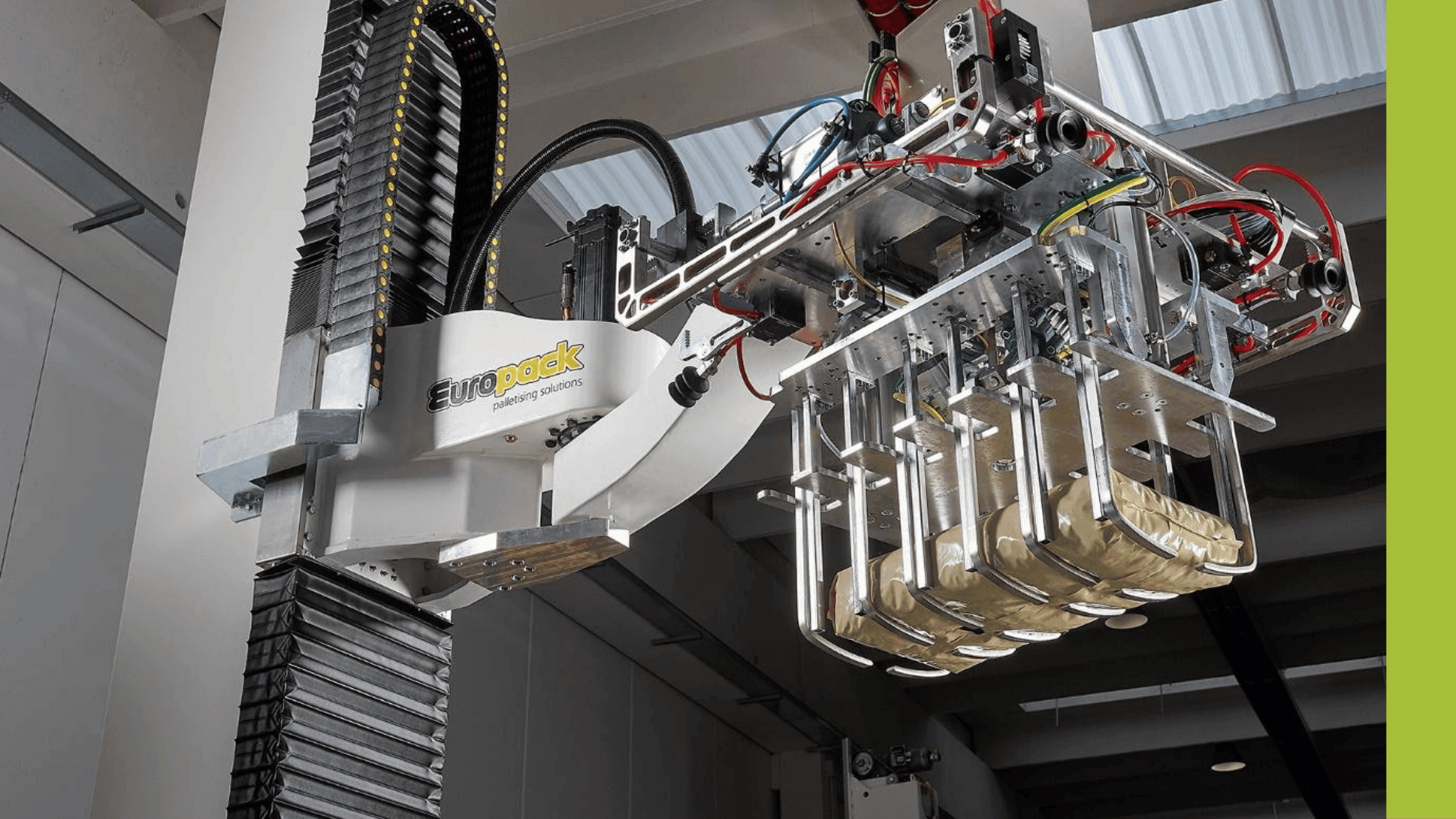

- Palletising

Each of these actions is repetitive and manual without the aid of machinery, and each step can trigger further concerns including hygiene, health and safety and productivity.

The manufacturing itself – the making of the product – is generally the first step to involve machinery or robotics, as it ensures uniformity of product. Automation is typically a step-change introduction, with elements bolted on as production demand or capacity grows.

Packing line automation

Following the manufacturing, items need to be packed, moved and potentially stored. This can all be automated, reducing the need for human interactions with the goods.

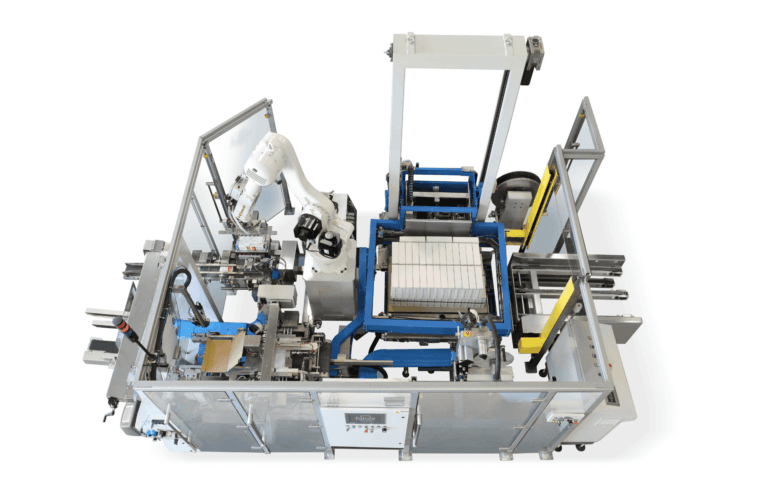

Automating your packing line involves transport, positioning and unit load formation equipment. These conveyor systems can be integrated with existing equipment to move, control and protect goods.

Packing line automation has benefits that include:

- Items are subject to fewer breakages

- It is a more hygienic process

- There is a lowered health and safety risk

- Requirement for decision-making is reduced

- Uniformity is maintained

- Improved efficiency with fewer errors

- Increased productivity

- Packing layout is optimised

We’re going to look at some of these benefits in more detail.

Automation means fewer breakages

Breakages are part and parcel of manufacturing – people drop jars or entire boxes, or forklift accidents happen and a pallet or two goes, and we obviously write these incidents off as human error. However, employing someone who happens to be clumsy on your shop floor could quickly add up.

Employing a machine instead, you will quickly find that not only are goods shifted smoothly and efficiently, there aren’t any breakages as the robotics are programmed to simply make the same motion with the same materials. These repetitive actions can become highly complex and refined, depending on requirements.

Packing line automation is lower risk

One of the huge draws of automation in a manufacturing environment is to combat the health and safety risk to the people who are undertaking repetitive actions that put strain on their bodies. Lifting product from A to B is always manual, and there are added health and safety risks with smaller spaces or where processes overlap.

PALpack’s packing line automation

We’ve been improving manufacturer productivity with automation for over 20 years, and this experience means you get the best possible solution, with an expert advising you at every step. Get in touch for more information.