We’ve covered the benefits of automation before, but now manufacturers seeking enhanced efficiency and lower costs are taking things a step further with customised systems.

Custom automation solutions are tailored to individual operations. Designed to meet the unique needs and challenges of specific businesses, they offer greater flexibility, improve quality and align with production demands, giving businesses competing in an increasingly demanding landscape a significant edge.

Developing a custom automation solution

At PALpack, we work closely with you to design a solution that not only meets your needs but optimises your operations. The collaborative process begins with a thorough consultation to understand your business and its goals, from which we develop a detailed scope of work that identifies the most suitable solutions.

Our engineers remain actively involved throughout the process, overseeing the project so every element is integrated into your existing operations with minimal disruption or downtime.

Diverse range of brands and solutions

Our partnerships with trusted European manufacturers give us access to a wide range of equipment. By combining palletisers, conveyors and other packaging equipment from leading suppliers, we can design and install bespoke solutions that deliver optimal performance, without changing the factory layout.

Leading brands we work with include:

Product customisation options

Each of our products can be customised in a variety of ways, offering maximum flexibility.

- Palletisers: This end-of-line equipment automates the packing process by sorting, transferring and stacking packages onto a pallet. These systems can be configured to work alongside existing production lines, with options for different stacking patterns and the ability to add functions such as banding and stretch wrapping to protect goods.

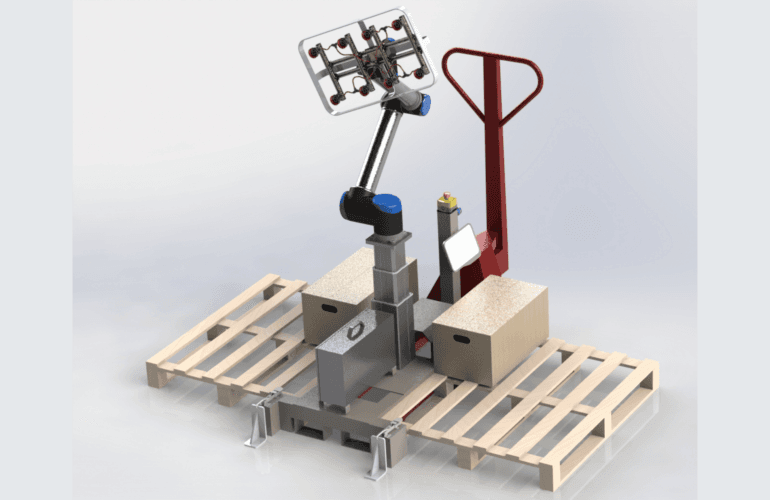

- Robot Palletisers: Ideal for assembling mixed pallets or handling different items simultaneously. Robot palletisers are cost-effective to install and can be programmed for specific product types and pallet configurations.

- Depalletisers: Used to unload items from pallets quickly and efficiently, these can be linked to conveyor systems and other handling equipment to improve throughput along the whole production line.

- Conveyor Systems: Designed to ensure packages reach the palletiser quickly and safely, systems can be tailored to your plant layout, the types of items being processed and other handling equipment.

- Sack Filling: Automated solutions for the high-speed filling, weighing and sealing of sacks come in two types, Vertical Fill Form Seal (VFFS) and pre-made sack filling machines. Both systems can be customised to accommodate different product types and packaging materials. The VAI range of VFFS sack-filling machines can integrate devices such as scales, conveyors and printers, removing the need for multiple separate pieces of equipment.

The benefits of customising solutions

Customisation helps businesses to innovate and adapt – not just in one area but across the whole operation.

Investing in tailored solutions streamlines processes, reduces errors and waste, enhances productivity and lowers costs. With a more consistent output, quality and customer satisfaction improve and with it, brand reputation. Custom solutions are also, by their very nature, highly adaptable, allowing businesses to respond to changing market conditions and scale up or down quickly and easily.