If you want to up the productivity of your manufacturing operation, you need to keep goods and materials moving efficiently around your facilities. One of the best ways to do this is by installing an automatic handling system and in this blog, we’ll look at what a handling system does and why they are so beneficial.

What is a handling system?

The term handling system refers to the machines and technology used to move, sort and pack materials and products throughout the production cycle. It may include conveyors, palletising equipment and other automated solutions that can work faster and harder than a human, speeding up processes to improve efficiency.

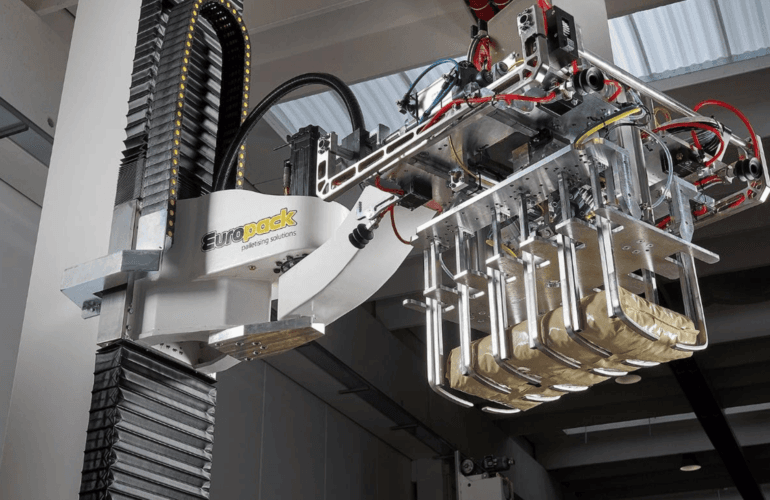

In a typical system, conveyors are used to move packages to a palletiser ready for stacking. The palletiser then uses a robotic arm or other mechanism to organise the products onto pallets in a predetermined configuration, ready for shipping or storage. This provides greater load stability and allows multiple loads to be moved at once.

What are the benefits of a handling system?

A well-designed handling system will integrate seamlessly with other palletising equipment already in place to streamline your operation, resulting in a cohesive manufacturing process. There are a number of other benefits too:

- Improved operational efficiency

Handling systems allow for tasks such as loading and unloading pallets to be automated, ensuring a reliable and continuous workflow. This not only accelerates production cycles but helps to minimise downtime and boost overall output. - Reduced labour requirement

This brings both financial and operational savings. By using machines to carry out repetitive and labour-intensive tasks, human operatives can be redeployed to focus on more strategic or skilled activities that add more value to the business. This increases job satisfaction and reduces the likelihood of manual handling injuries occurring. - Greater accuracy and precision

Automated systems are designed to perform the same tasks with exacting precision, minimising the margin of error and reducing wastage. In turn, this results in a more consistent and higher quality end product, improving customer satisfaction, loyalty and repeat business.

Choosing a handling system

The choice of handling system depends on the specific needs of the manufacturing or distribution process and at PALpack we have extensive experience that allows us to recommend the best equipment for your operation.

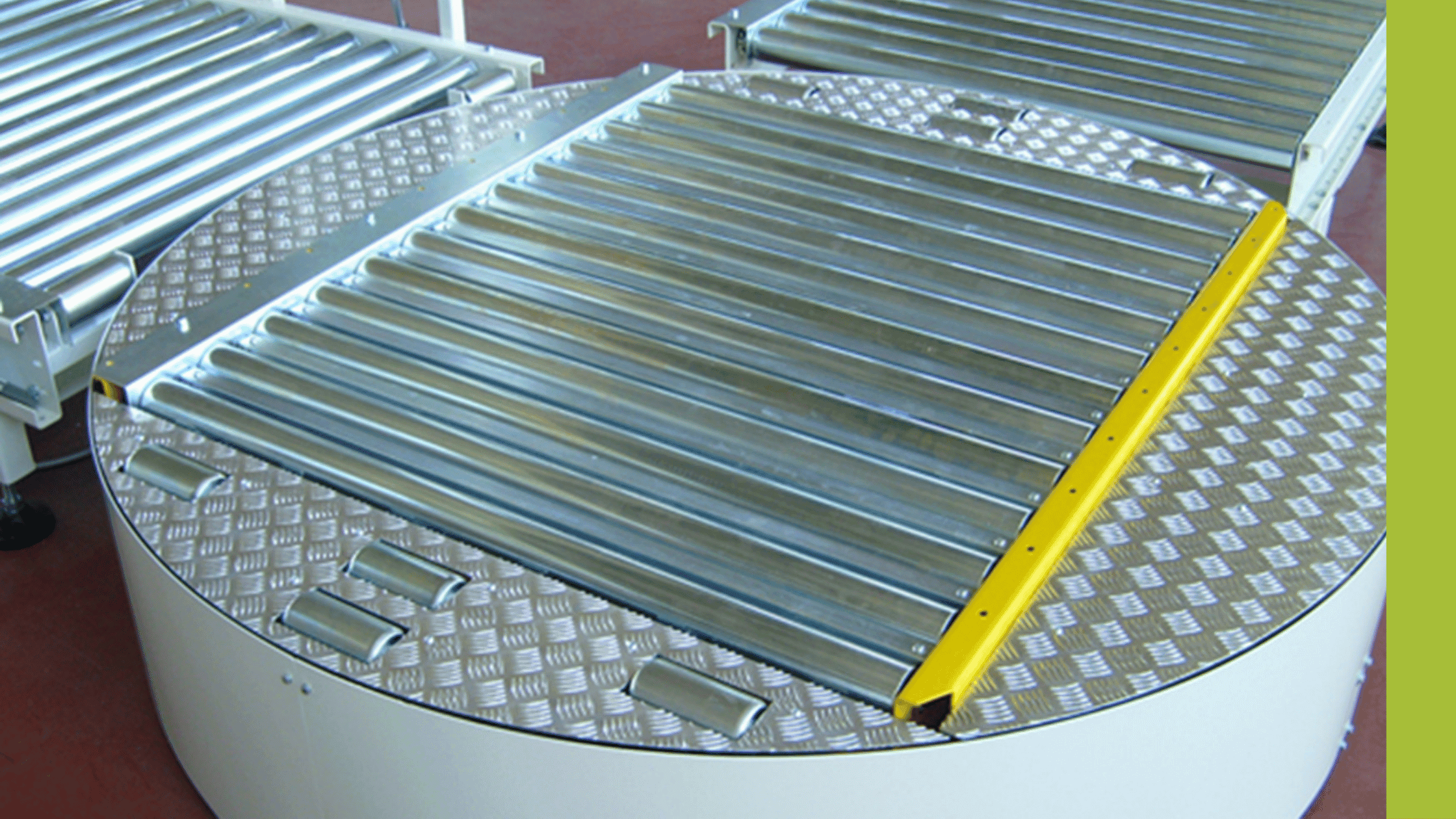

Conveyor systems are a vital part of the production process, especially for unit load formation, and are designed according to the typology, plant layout and types of items to be palletised. Different products require different methods of handling and we always seek to understand your specific needs before any installation.

We only work with trusted providers and Lita is one of the world’s oldest manufacturers of palletising and handling systems, known for its exceptional design and build standards. Established in 1962 and still a family-owned company, its machines have been installed around the world in sectors from food to cosmetics.

The company specialises in conventional medium to high-paced palletisers, installed in tandem with other handling equipment including bottle conveyors, pallet conveyor systems, vertical elevators and pack dividers.

Many of our previous blogs have covered how automation can improve the overall effectiveness and efficiency of a manufacturing operation and handling systems are another tool to be considered. Whatever your requirement or type of operation, they can play a crucial role in improving customer service, lowering costs and staying competitive.