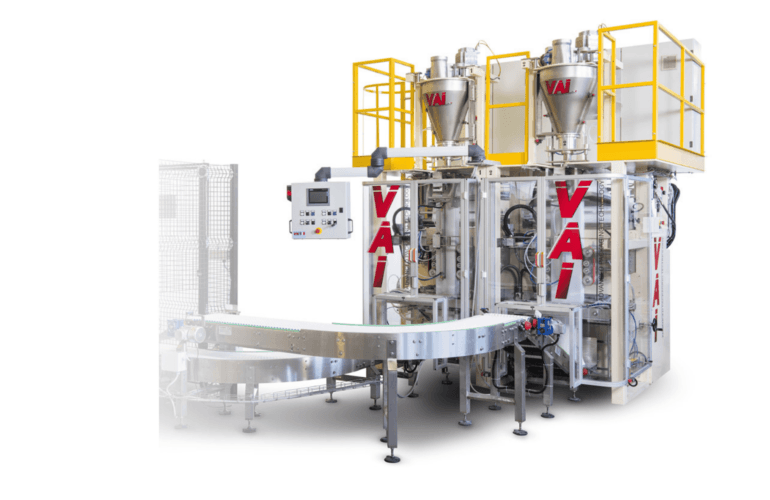

Manufacturers looking to maximise efficiency must embrace automation at every stage of their operations, from product handling to final packing. At PALpack, we’re working with a new partner to enable exactly that.

Gampack Group provides a wide range of packaging machinery, combining industry expertise with cutting-edge technology to create secondary packaging solutions that are not only functional but also sustainable.

About Gampack Group

One of Europe’s best-known suppliers of high-quality flexible packaging solutions, Gampack Group has been at the forefront of packaging technology for over 20 years. The Italian company is built on a foundation of precision engineering and a deep understanding of the importance of packaging, and has built a reputation for reliability, excellence and expertise across 54 countries and a diverse range of industries.

Why choose Gampack Group?

Specialists in secondary packaging, Gampack prides itself on providing turnkey, highly customised end-of-line solutions tailored to manufacturers’ needs – something which we at PALpack are also dedicated to offering.

The group’s range of equipment is vast and includes palletisers as well as different machines used to improve efficiency upstream, including:

- Wrap-around case packers – efficiently pack products into wrap-around cases for enhanced stability

- Vertical packers – designed for high-speed vertical packaging applications

- Modular cartoning machines – manage various carton sizes and configurations

- Shrink wrappers – securely bundle and wrap multipacks for transportation

- Handle applicators – add handles for improved portability and convenience

Gampack’s machines are also designed to adapt quickly to different packaging sizes and types. From rigid containers such as jars and tins to flexible and semi-flexible packaging including pouches and juice cartons, this delivers maximum flexibility, reducing downtime and increasing productivity.

Innovative solutions

Continuous investment in new technology and developments means Gampack’s products offer enhanced operational efficiency. Intuitive software is developed in-house and the integration of AI and smart monitoring allows for features such as real-time status tracking, optimised energy consumption, remote operation and predictive maintenance.

In addition to software innovation, Gampack has also developed monoblock solutions and space-saving layouts, including a patented system that compacts production spaces. Rather than placing machines in a straight line, they’re placed side by side, reducing the overall footprint. Different machines can also be combined in a single system with the addition of specific modules, such as cover overlap application or film wrapping, saving further space and energy consumption.

Focus on sustainability

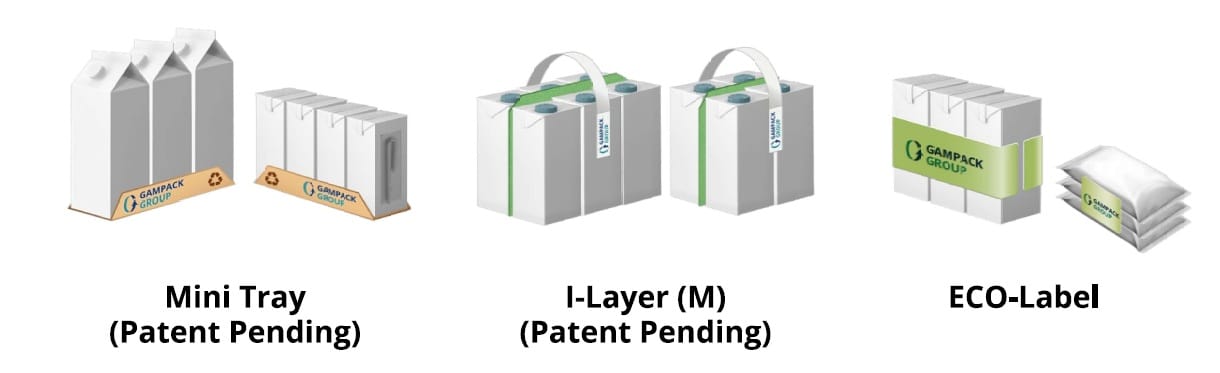

Sustainability is another key priority and Gampack’s Green Line focuses on minimising waste and environmental impact while maintaining efficiency.

- The Mini Tray uses a tiny flat blank to join the products by wrapping only their base, leaving the rest of the package free from covering. This reduces unnecessary packaging and maintains brand visibility.

- The Eco Label is a paper-based adhesive label placed midway up the containers to hold them together. This allows the creation of multipacks without the use of plastic, making the packaging 100% recyclable.

- The I-Layer is an eco-friendly alternative to shrink wrap. The product units are glued to a vertical interlayer and can also be equipped with a handle for transport.

In addition to these solutions, trays with quarter and a half pallets made from recyclable paper have been introduced.

Sustainability has also been incorporated in other ways, with energy-efficient motors and systems and user-friendly machines that enhance operational efficiency and comfort for users while reducing downtime and energy consumption.

We’re delighted to be working with Gampack and bringing more of its cutting-edge automation, innovative technology, and sustainable solutions to our clients.

Want to find out more? Discover how Gampack can transform your production line today.